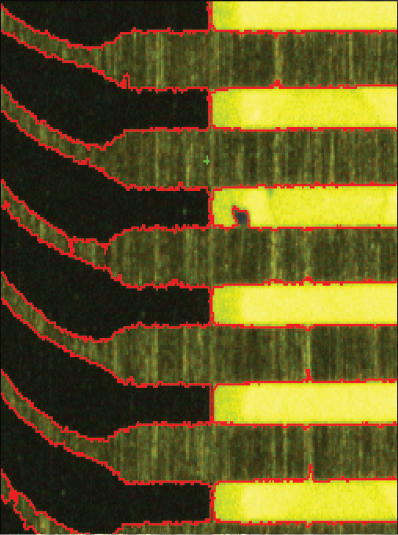

Pixen 6 utilizes high performance 12M camera technology to meet extreme throughput requirements. Our OnDemandHR-function switches easily between resolutions of 23 or 7 µm/pixel without diminishing image field size, in order to meet future inspection requirements.

In addition, the inspection system offers color evaluation capabilities. The user interface is based on a model-oriented component library and intuitive programming.

The operator virtually sees the component before his eyes, to make programming easy and convenient. The essential functions of EasyPro are a user-friendly user interface, intelligent data import and the IPC-compliant inspection library, which enables inspection plan creation in only three steps. As a central feature, TrustedChange integrated defect verification greatly simplifies the reduction of false alarms while ensuring virtually zero defect escapes.

The integrated defect verification tool uses stored image data of classified defects and golden boards to simulate a test run with all validated production results. Inspection program quality can be confirmed at any time, whether for in-house production needs or for documentation during customer audits.

The operator virtually sees the component before his eyes, to make programming easy and convenient. The essential functions of EasyPro are a user-friendly user interface, intelligent data import and the IPC-compliant inspection library, which enables inspection plan creation in only three steps. As a central feature, TrustedChange integrated defect verification greatly simplifies the reduction of false alarms while ensuring virtually zero defect escapes.

The integrated defect verification tool uses stored image data of classified defects and golden boards to simulate a test run with all validated production results. Inspection program quality can be confirmed at any time, whether for in-house production needs or for documentation during customer audits.

- Easy Program Creation,High Throughput,Low Maintenence

- Highest inspection depth with 12M cameras

- Selective high resolution with OnDemandHR-function

- Color Evaluation

- Fast Program creation with Easy Pro

- Boat/Tray Mapping

- Optional to Attached with Robotic Sorting

- Up-gradable to Multiple Cameras Process to Increase UPH

- SPC Software % by Reject Criteria